- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-09-30 Origin: Site

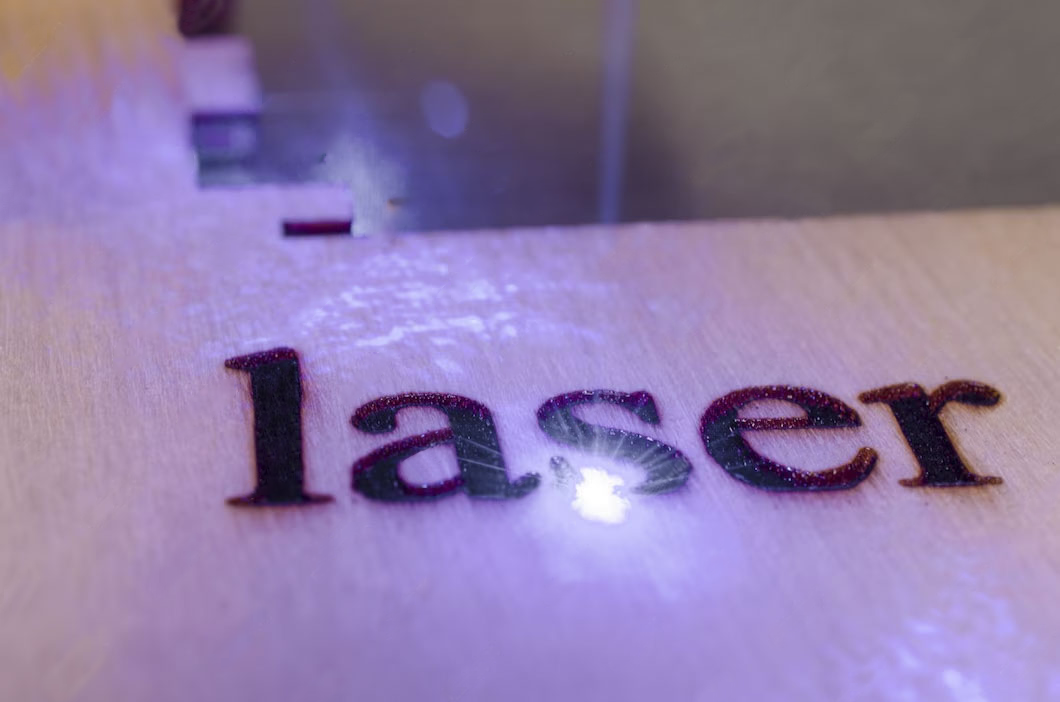

If you`re in production, you`ve likely puzzled which laser marking system suits your needs—and a way to select a dependable laser marking system supplier. CO₂, UV, and fiber options (consisting of fiber laser marking system, UV laser marking system, and CO2 laser marking system) every have precise strengths, however fiber laser fashions had been taking up factories worldwide. Let`s spoil down what makes every kind tick, in which they paintings nice (from laser marking system for glass to laser marking system for stainless steel), and why fiber machines are getting vital for production automation.

1. How CO₂, UV, and Fiber Laser Markers Work (Key Differences)

Not all laser marking machines are the same—their wavelengths and cloth compatibility set them apart. Here`s a sensible breakdown:

CO2 Laser Marking Machine: For Non-Metal Workhorses

A CO2 laser marking system makes use of a 10.64μm infrared wavelength that heats non-metallic surfaces to vaporize or discolor them. Think of it as a precise “warmness pen”—it`s the pinnacle laser marking system for leather-based, laser marking system for plastic, and paper products. You`ll spot it on leather-based telecellsmartphone cases, cardboard packaging, or timber present tags. Most CO2 laser fashions have high-velocity scanning (as much as 7,000mm/s), ideal for bulk jobs like printing emblems on plastic bottles.

The catch? It can`t mark naked metallic—you`d want a unique coating, which provides to laser marking system value and manufacturing steps. For small workshops, a compact CO2 laser marking system may appear budget-pleasant upfront, however long-time period maintenance (changing laser tubes yearly) provides up.

UV Laser Marking Machine: The Precision Expert for Delicate Materials

A UV laser marking system is based on a 355nm ultraviolet wavelength for “bloodless processing”—it breaks molecular bonds as opposed to heating, so no warping or damage. This makes it a standout glass laser marking system (frequently referred to as the nice laser marking system for glass) and best for warmness-touchy gadgets like clinical syringes or telecellsmartphone microchips. It additionally handles obvious plastics and silicon wafers with 0.01mm accuracy—some thing no CO2 laser can match.

But UV laser fashions have tradeoffs: they`re slower (3,000–5,000mm/s) than fiber laser options, and their preliminary laser marking system value is higher. Still, for industries like prescription drugs that want perfect qr code laser marking on tiny parts, a UV laser marking system is non-negotiable.

Fiber Laser Marking Machine: The All-Rounder for Metals & More

A fiber laser marking system makes use of a 1064nm near-infrared wavelength, powered with the aid of using a fiber laser that`s green and durable. It`s the closing laser marking system for stainless steel, aluminum, copper, or even engineering plastics—making it a staple in electronics and vehiclemobile production. A 30w fiber laser marking system, one of the maximum famous small laser marking system options, balances strength and portability for small-to-medium businesses (SMBs).

2.Uses, Pros, and Cons: Detailed Breakdown

To simplify your choice, let`s stroll thru how every laser marking device plays throughout substances, strengths, weaknesses, and realistic metrics—which includes area of interest makes use of like 3d laser marking device capabilities (a developing fashion in commercial marking).

When it involves cloth compatibility, CO2 laser marking machines excel with non-metals: they`re the go-to for laser marking device for leather-based, laser marking device for plastic, wood, and paper, however most effective paintings on metals in case you upload a unique coating. UV laser marking machines, through contrast, are the pinnacle laser marking device for glass, obvious plastics, and silicon—additionally they paintings on a few smooth alloys, however their actual electricity is warmth-touchy substances like scientific devices. Fiber laser marking machines are the maximum versatile: they deal with all metals (ferrous and non-ferrous, making them the great laser marking device for stainless steel) and plenty of non-metals like engineering plastics or covered ceramics. They`re additionally main the rate in 3d laser marking device tech, with fashions that may mark curved steel prototypes or complicated surfaces.

For strengths, CO2 laser marking machines stand out for low in advance laser marking device fee and speedy non-steel marking—tremendous in case you most effective paintings with substances like leather-based or plastic. UV laser marking machines shine without a warmth harm and ultra-first-rate precision (0.01mm accuracy), that's crucial for qr code laser marking on microchips or glass components. Fiber laser marking machines, though, provide the widest variety of benefits: they paintings with maximum substances, use minimum energy, have an extended fiber laser lifespan, and combine effortlessly with production automation tools.

Weaknesses range too: CO2 laser marking machines can`t mark naked steel and want common laser tube replacements, riding up renovation expenses. UV laser marking machines are sluggish for bulk jobs and feature better preliminary laser marking device fee. Fiber laser marking machines conflict with absolutely obvious substances, however that is a small tradeoff for his or her standard versatility.

In phrases of velocity, CO2 laser marking machines hit 5,000–7,000mm/s, making them speedy for non-steel bulk paintings. UV laser marking machines are slower at 3,000–5,000mm/s, considering their precision calls for extra time. Fiber laser marking machines stability velocity and accuracy at 6,000–8,000mm/s—best for excessive-quantity commercial marking like qr code laser marking on digital components. Maintenance expenses comply with a comparable pattern: CO2 fashions have excessive expenses because of every year tube swaps, UV fashions have low expenses (no transferring components of their lasers), and fiber fashions have very low expenses way to their modular fiber laser design.

3. Why Fiber Laser Marking Machines Dominate Industrial Marking

Industrial marking needs reliability, pace, and flexibility—and fiber laser marking gadget assessments all boxes. Here`s why they`re taking over:

Market Growth & SMB Adoption

QYResearch`s 2025 record indicates the worldwide fiber laser marking gadget marketplace developing at 12% yearly, hitting $1.five billion in 2024. SMBs are riding this: 68% now use fiber laser fashions (up from 45% in 2020). A 30w fiber laser marking gadget, a compact small laser marking gadget, is best for workshops with constrained area however various needs—like marking chrome steel screws one hour and plastic circuit forums the next.

Real-World Benefits for Manufacturing Automation

One gadget, 70% of jobs: A fiber laser marking gadget replaces more than one tools (no want for separate CO2 or UV fashions except you specialise in glass). This cuts laser marking gadget price long-time period and saves ground area.

Seamless automation: It integrates with production automation systems—pulling orders automatically, monitoring marks, and lowering human mistakess with the aid of using 65%. For example, an vehiclemobile elements plant makes use of a fiber laser for qr code laser marking on aluminum frames, linking every mark to manufacturing data.

Durability for commercial marking: A fiber laser`s 100,000-hour lifespan manner it runs reliably in harsh manufacturing unit conditions—important for commercial marking that can`t find the money for downtime.

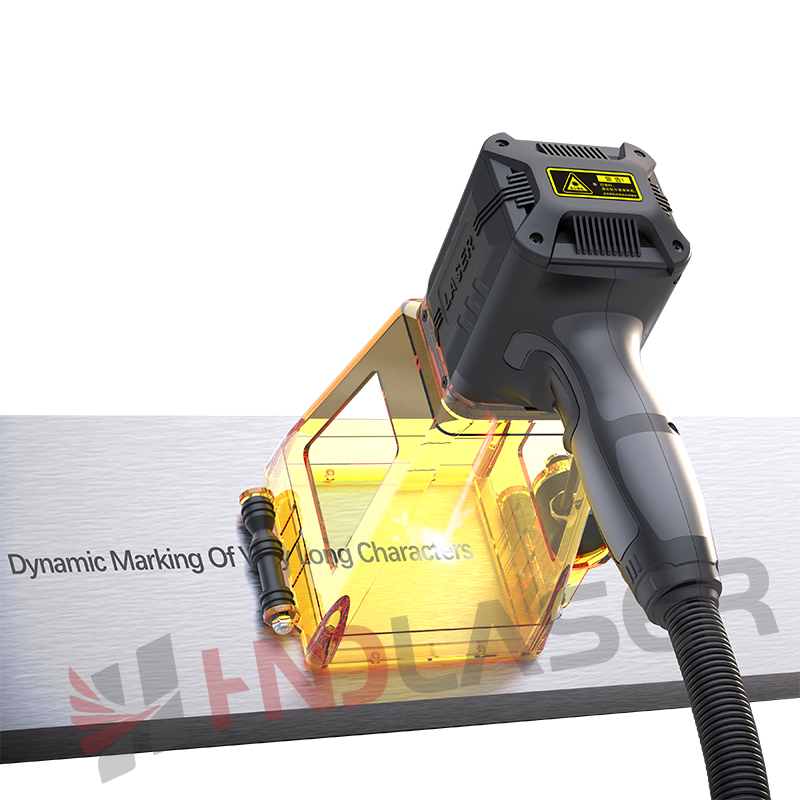

4. Handheld vs. Desktop Laser Markers: Portable vs. Precision

Once you select a laser type (like fiber), you`ll select out among hand-held laser marking gadget (aka transportable laser marking gadget) and laptop laser marking gadget. Here`s how they compare:

Handheld Laser Marking Machine (Portable Laser Marking Machine)

A hand-held laser marking gadget—regularly referred to as a transportable laser marking gadget—weighs beneathneath 5kg, runs on batteries (6–eight hours consistent with charge), and has a touchscreen for on-the-move use. It`s best for big or immovable items: assume laser marking gadget for chrome steel beams on creation sites, field IDs, or custom furnishings engraving (it really works as a compact laser marking gadget for leather-based too).

The tradeoff? Accuracy is ±0.1mm—tremendous for large emblems or text, however now no longer for tiny qr code laser marking. For corporations that want on-webweb page commercial marking (like HVAC technicians marking steel ducts), a hand-held laser marking gadget is a game-changer.

Desktop Laser Marking Machine

A laptop laser marking gadget remains fixed, with a worktable and CCD digital digicam for automated alignment (accuracy ±0.05mm). It`s the pinnacle small laser marking gadget for bulk jobs: marking telecellsmartphone case serial numbers, earrings engravings, or scientific device qr codes at 1–three seconds consistent with item. Most laptop fashions are fiber laser marking machines (just like the 30w fiber laser marking gadget) or UV laser marking machines (for glass elements).

They want energy and area, however their pace makes them crucial for production automation—many connect with CNC systems, performing as cnc laser marking gadget for precise, repeatable marks.

5. How to Choose the Right Laser Marking Machine (With Supplier Tips)

Use this tick list to slim down options—with enter from pinnacle laser marking system suppliers:

Marking metal (specifically stainless-steel): Go for a fiber laser marking system (30w fiber laser marking system is a secure wager for SMBs).

Working with glass or heat-touchy plastics: A UV laser marking system (aka laser marking system for glass) is really well worth the investment.

Only non-metals (leather, plastic): A CO2 laser marking system cuts in advance laser marking system cost.

On-webweb page jobs: Handheld laser marking system (transportable laser marking system) for flexibility.

Bulk small parts: Desktop laser marking system (small laser marking system length suits maximum workshops).

Emerging needs (curved surfaces): Ask your laser marking system dealer approximately 3d laser marking system accessories for fiber or UV models.

What`s Next for Laser Marking?

The destiny leans into flexibility: hybrid machines (fiber + UV) that transfer among tasks, AI-powered settings that adapt to materials, and 3d laser marking system tech that handles curved surfaces. As production automation advances, laser marking machines turns into even greater connected—monitoring each mark from manufacturing to delivery.

For maximum businesses, though, the solution is clear: a fiber laser marking system (paired with a hand-held laser marking system for on-webweb page work) gives the first-class stability of versatility, cost, and performance. To get started, associate with a laser marking system dealer that gives demos—take a look at how a 30w fiber laser marking system handles your particular materials (like stainless-steel or plastic) earlier than buying.

At the stop of the day, the proper laser marking system isn`t only a tool—it`s a manner to make your manufacturing faster, greater reliable, and prepared for the needs of contemporary-day production.