- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-10-15 Origin: Site

You see laser marking machines are changing how people work in factories. These machines are very fast and very accurate. You can mark many materials quickly. The marks stay forever and are easy to see. Laser marking machines work better than old ways. They help you do more work and stop less often. More people around the world want these machines. The market could be worth over $6 billion by 2032. Asia Pacific is growing the fastest. This new technology helps you follow strict rules for being efficient and keeping track of things.

Laser marking machines are very accurate and fast. They can mark up to 1,500 items every hour. This helps factories work much faster.

These machines can mark many types of materials. They work on metals, plastics, and ceramics. This makes them useful for many businesses.

Factories save a lot of money with laser marking. They do not need inks or solvents. This means less waste and lower repair costs.

Laser marking makes marks that last a long time. The marks do not fade away. This helps track products and follow rules in the industry.

Factories can use laser marking with smart machines. This makes work even faster and easier. It also helps factories be better for the environment and ready for new problems.

Factories need to work fast and be exact. Laser marking machines help with both. These machines can make very accurate marks. They work on many shapes and materials. Fiber laser marking systems can mark with an accuracy of ±0.01 mm. This is great for metals like stainless steel, aluminum, and copper. UV laser marking machines are good for plastics and glass. They use cold marking, so there is no heat damage. MOPA fiber laser marking systems let you control the heat. This helps with color marking on stainless steel or black marking on aluminum.

Machine Type | Precision Level | Best For |

|---|---|---|

Fiber Laser Marking System | ±0.01 mm marking accuracy | Metals (stainless steel, aluminum, copper) |

UV Laser Marking Machine | Cold marking, no heat-affected zone | Plastics, glass, silicon, sensitive substrates |

MOPA Fiber Laser Marking System | Variable pulse width for heat control | Color marking on stainless steel, aluminum black marking |

Laser marking machines are much faster than old ways. You can make detailed designs quickly. You can reach hard spots without touching the product. The marks last a long time. This is important for keeping track of things in smart factories. You do not need to stop for repairs often. Your work keeps going. You save time and make fewer mistakes. This helps you make more products.

Tip: Laser marking machines can mark up to 1,500 units each hour. Manual marking only does about 450 units per hour. This speed helps you keep up with busy factories.

You want a machine that works on many materials. Laser marking machines can do this. You can use them on plastics, ceramics, glass, composites, organic materials, and semiconductors. This makes them useful in many jobs, like electronics and medical devices.

Material Type | Applications and Benefits |

|---|---|

Plastics | Permanent, clean, and efficient identification across various plastics used in manufacturing. |

Ceramics and Glass | Non-contact, contamination-free marking ideal for fragile surfaces in electronics, medical devices, and luxury goods. |

Composites | High-quality identification on difficult materials like CFRP and anodized metals without thermal damage. |

Organic Materials | Flexible applications for functional and decorative purposes, yielding precise and lasting results. |

Semiconductors | Sophisticated marking solutions for identification and traceability in technology sectors. |

Laser marking machines can mark on curved or odd shapes. 3D laser marking technology helps with this. You can mark slanted or round objects. The machine changes to fit the shape. You get clear marks every time. You do not need to move the product or use extra tools. This is better than old marking methods.

Laser marking machines are good for small and detailed work. They help with electronics, medical devices, and luxury goods. These jobs need very accurate marks. Laser marking machines make this easy.

You want to spend less money and waste less material. Laser marking machines help you do this. You do not need inks or solvents. This saves you money on supplies. You do not need much maintenance. This means fewer repairs and less waiting.

Marking Method | Cost per Mark | Consumables Required | Maintenance Needs |

|---|---|---|---|

Laser Marking | $0.02 | No | Low |

Traditional Methods | $0.07 or more | Yes (inks, solvents) | High |

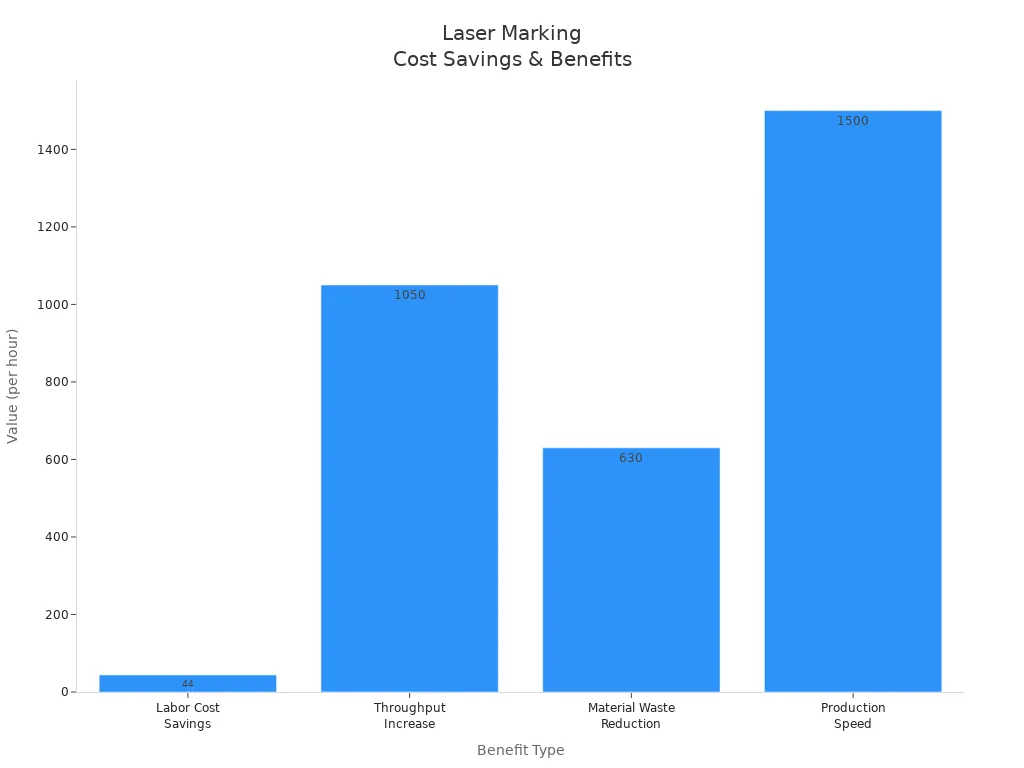

You also save money on workers. Laser marking machines can save you about $44 each hour in labor. You can make 1,050 more units per hour than manual marking. Material waste drops from 4% to just 0.5%. This saves you $630 each hour. The marks last longer. You do not need to mark or label products again.

Laser marking machines help keep your work clean. The process does not touch the product. This means less contamination. You do not scratch or damage the product. Your products look better and have fewer problems.

Note: Using laser marking machines helps you work faster, spend less, and make better products. Your factory becomes more efficient and dependable.

Laser marking machines use a special process called LASER. LASER means Light Amplification by the Stimulated Emission of Radiation. This process makes a strong beam of light. The machine excites certain materials to release photons. The beam is very powerful. It can mark, engrave, or change many surfaces with high accuracy. This is why laser marking machines are popular in factories.

Mechanism | Description | Application Example |

|---|---|---|

Engraving | Takes away material to make a deep mark. | Carving initials into a surface. |

Ablation | Turns material into vapor for a clean mark. | Marking delicate materials. |

Annealing | Heats up material to change its color. | Markings on surgical instruments. |

Foaming | Makes gas bubbles for raised marks. | Raised lettering on keypads. |

Laser marking machines are fast, accurate, and flexible. You can make detailed designs quickly. You can use them on metals, plastics, and organic materials.

Fiber laser marking machines are known for being very precise and fast. You can use them to engrave or mark metals and hard plastics. These machines work at a wavelength of 1.064 micrometers. This is good for many factory jobs. Fiber lasers are used in aerospace, cars, and machines. They last a long time and need little fixing.

Fiber laser marking machines make clear marks very quickly.

You can use them for small details on many materials.

They help you keep up with busy factory work.

Fiber lasers can last up to 100,000 hours, so you fix them less.

Fiber laser technology helps you save money. You get good results and less waiting for repairs.

Laser marking machines use non-contact processing. The laser does not touch the product. This stops scratches, dents, or other damage. This is important for fragile things like silicon wafers or medical devices. Non-contact marking keeps your products clean and safe from dirt.

Advantage | Description |

|---|---|

Non-contact | No damage or stress to the parts being marked. |

Indelible marks | Permanent markings that do not fade or wear off. |

Precision placement | Accurate marking even on curved or irregular surfaces. |

Corrosion resistant | Marks can withstand cleaning and sterilization processes. |

Low maintenance | No need for inks or solvents, reducing costs and effort. |

You can trust laser marking machines to give you the same results every time. You get clear, lasting marks. This helps you follow strict factory rules and supports new laser technology for the future.

Laser marking machines are used a lot in making cars. They put a special code on every car part. This code helps you know where each part goes. You can mark metal, plastic, and rubber parts. The marks do not fade or rub off. They are clear and last a long time. The marks are very exact and strong. The machine does not touch the part, so it does not get hurt.

Give each part its own code.

Make sure parts are good and safe.

Use one machine for many materials.

Stop damage and keep parts looking new.

Making electronics needs small and clear marks. Laser marking machines help you label tiny parts. You can mark chips and circuit boards. You can put codes on wafers and other small things. The marks stay easy to read and do not go away. You can work fast and make lots of products.

Industry | Application Description |

|---|---|

Microelectronics | Label, trace, and identify products, like putting codes on wafers. |

Healthcare | Make marks that last and are safe for medical tools, like UDI codes. |

Aerospace | Put serial numbers and barcodes on parts to help follow safety rules. |

You must follow tough rules when making medical devices. Laser marking machines help you do this. You can make marks that cannot be changed. This stops fake products. You can track each group of products. You can recall them fast if needed. The marks help you keep quality high and keep people safe.

Make sure products are real with special marks.

Follow FDA and EU rules for medical devices.

Recall products quickly and check quality.

Track groups of products and manage supplies.

Tip: Laser marking machines help keep people safe and help you follow the law.

Aerospace parts need marks that last a long time. Laser marking machines put codes on every part. These codes help you track parts for their whole life. The marks are very exact and do not hurt the part. This keeps the part strong and safe.

Benefit | Description |

|---|---|

Permanent and Durable Markings | The code stays clear for the part’s whole life and helps you track it. |

High Precision and Accuracy | The marks are tiny and exact, so you can tell parts apart. |

Non-contact and Non-destructive | The machine does not touch the part, so it does not get damaged. |

Laser marking machines help make sure aerospace parts are good. You can trust the marks to last and help you follow the rules.

You want your factory to work faster and better. Laser marking machines help you do this. You can mark 1,000 to 3,000 parts each hour. This is much faster than silk screen printing. That old way only marks 300 to 500 parts per hour. Laser marking machines set up in just 5 to 10 minutes. Silk screen printing takes much longer, about 30 to 90 minutes. You save a lot of time when you switch jobs. You can connect laser marking machines to robots or other machines. This means you do not need to stop or use extra workers. Your factory keeps moving and works better.

Fast marking helps you make more products.

Quick setup saves time and work.

Automation lets you keep making things without stopping.

Tip: You can save lots of marking messages in the machine. This makes it easy to change what you mark and keeps your line working well.

You need to keep track of every product you make. Laser marking machines give each part a mark that lasts. You can mark very small parts with great detail. You can add 2D barcodes or QR codes with lots of information. These machines work on metals, plastics, and ceramics. You can set them up to work by themselves for even more speed. Each part can get its own special number. This helps you follow world rules for tracking and keeps products safe.

Marks last a long time for good tracking.

Small parts get clear, sharp marks.

Codes hold lots of data for better tracking.

Works on many kinds of materials.

Easy to use with machines for more speed.

Each part gets its own serial number.

The laser does not touch the part, so it stays safe.

Fast marking helps your factory work better.

Software lets you change things quickly.

The machine checks marks to make sure they are right.

Note: Laser marking machines help you follow tough rules for tracking and working fast in factories.

You want to use your materials well and not waste them. Laser marking machines help you do this. The marks are exact, so you do not need to fix mistakes. You do not use ink or tape, so there is less trash. The laser does not touch the product, so it does not get hurt. Marks last a long time, so you do not need to redo them. You use less energy and keep your work fast.

Aspect | Impact on Waste Reduction |

|---|---|

Precision | Good marks mean less waste and fewer mistakes. |

Elimination of Consumables | No ink or tape, so less trash is made. |

Non-Contact Process | Keeps products safe and stops waste. |

Durability of Marks | Marks last, so you do not need to redo them. |

Energy Efficiency | Uses less power for better work. |

Adaptability | Works on many things, so you use materials better. |

Minimal Maintenance | Fewer repairs mean less waste and more work time. |

Optimized Material Usage | Only removes what is needed, saving materials. |

Laser marks do not fade or wear away.

You do not need to redo or replace things as much.

You help keep your factory safe and follow the rules.

Callout: Laser marking machines help you work better, waste less, and track everything in your factory.

Factories are becoming smarter every year. Laser marking machines help make this happen. When you connect these machines to Industry 4.0 systems, you can watch and control them all the time. IoT sensors inside the machines check how well they work, their temperature, and how much power they use. This information helps you find problems early and fix them fast. AI systems can change how the machine marks things for better results. Smart systems keep track of every mark for better traceability and product authentication. Your factory works better and gets ready for new ways of manufacturing.

Watching machines in real time helps factories work better.

Fixing problems before they stop work keeps machines running.

Smart connections help you track products and work faster.

Note: Laser marking machines help you gather data, look at it, and make quick changes. This helps your factory stay strong and ready for new trends.

Automation is changing how factories work. Laser marking machines fit well with automated lines. You can use them with robots and other smart machines. This lets you mark products quickly and very accurately. You do not need to touch the product, so it does not get damaged. Direct laser marking makes products safer and harder to copy. More factories use automation, so laser marking machines are becoming even more important.

Smart factories use AI to make marking better.

Automated systems mean less manual work and fewer mistakes.

Accurate marking is needed for electronics and cars.

Callout: Using automation with laser marking machines gives you faster, safer, and more dependable results. This is very important for the future of manufacturing.

Factories want to be more sustainable in the future. Laser marking machines help with this goal. They use less energy because they are designed to be efficient and have low-power standby modes. You make less waste since the laser only removes what is needed. Eco-friendly machines use safe materials and special air filters. This keeps your workplace clean and lowers pollution. You do not need inks or chemicals, so workers and the environment stay safe.

Aspect | Description |

|---|---|

Energy-Efficient | Uses less power but still works well. |

Waste Reduction | Precise marking means less material is wasted. |

Safe Materials | No toxic chemicals are used in the process. |

The market for laser marking machines is growing quickly. Experts think it will go from $3.03 billion in 2024 to $4.35 billion by 2029. This shows how important these machines are for the future and for meeting new sustainability rules.

Tip: Choosing laser marking machines helps your factory be cleaner, greener, and work better for the future.

Laser marking machines are changing how factories work today. They help you work faster and more accurately. You can make strong marks that last on many things. This helps you save money and make more products. You can follow tough rules for quality and tracking. These machines last a long time and do not break often. They help the planet by making less waste and using fewer chemicals. New technology helps you check your work better. You can pick the right machine for any job. Automation helps you finish work faster. Your factory stays strong and ready for the future.

Key Takeaway | Description |

|---|---|

Precision | You get clear, high-quality marks on all materials. |

Durability | You can count on these machines to last a long time. |

Cost-effectiveness | You spend less money and waste less material. |

Environmental | You help the planet by making less waste and using fewer chemicals. |

Technology | You use new systems for better checks and faster work. |

Customization | You can choose machines for every job in your factory. |

Productivity | You make more products with smart machines. |

You can track products better than before.

You follow all the rules for quality.

You need marks that are always clear and last a long time.

Tip: You can keep your factory ahead by using laser marking machines for better quality and new ideas.

Factories use laser engraving machines to mark products. These machines can add serial numbers, barcodes, and logos. You can use them on metals, plastics, and glass. Many industries trust these machines for clear marks that last.

Laser engraving machines make marks that are exact and permanent. You do not get smudges or fading. You can make detailed designs with these machines. They help you meet tough quality rules. Laser engraving machines work better than old marking ways.

Yes, you can use laser engraving machines on many things. You can mark metals, plastics, ceramics, glass, and wood. The machine changes settings for each material. You get sharp marks every time. Factories like laser engraving machines for this reason.

Laser engraving machines have shields and covers for safety. These protect your eyes and skin. You do not need to touch the product. Laser engraving machines lower the chance of injury. They help keep your workspace clean and safe.

Laser engraving machines let you put special codes on products. You can track items from start to finish. The marks stay clear and last a long time. You meet rules for tracking products. You can scan and check items easily with these machines.

Tip: Laser engraving machines help you follow safety and quality rules in your factory.

Benefit | How Laser Engraving Machines Help |

|---|---|

Product Tracking | Unique codes for every item |

Quality Control | Clear, permanent marks |

Material Flexibility | Works on many surfaces |

Worker Safety | Non-contact, shielded process |

Fast Production | Quick and accurate marking |