- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-11-13 Origin: Site

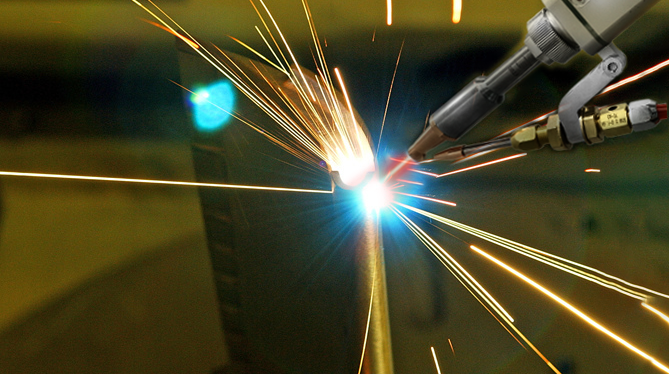

Introduction: A New Era of Welding Technology

In the unexpectedly evolving international of contemporary-day production, welding stays one of the maximum important commercial processes. Whether it`s the development of automobiles, aerospace components, or high-precision scientific devices, welding acts because the spine that connects steel systems together. Over the beyond decade, laser welding machines have emerged as a innovative opportunity to standard welding strategies, presenting unequalled speed, strength, and precision. As industries embody clever production and automation, expertise the important thing variations among laser welding and conventional welding turns into critical for each commercial laser producer and laser device dealer striving to live aggressive in 2025 and beyond.

1. Understanding the Working Principles

(1)How Laser Welding Works

A fiber laser welding gadget makes use of a high-strength laser beam as its warmness source. When the focused beam hits the steel surface, it unexpectedly melts and fuses substances together, forming a sturdy weld seam with minimum warmness distortion. The laser device producer designs this procedure to make certain precision control — with beam cognizance accuracy frequently inside 0.01 mm. Unlike conventional strategies, the laser welding gadget operates with minimum contact, lowering infection and generating clean, uniform welds. Thanks to technology like CNC laser welding structures and three in 1 laser welding cleansing reducing machines, operators can now gain deep-penetration welds at wonderful speeds.

(2)Traditional Welding: The Old Workhorse

Conventional welding methods, such as MIG/TIG and arc welding, melt and fuse joints using electric arcs or filler materials. Despite their dependability and affordability, these techniques increase the risk of material deformation by creating sizable heat-affected zones (HAZ). In large-scale industrial applications, consistency is challenging because manual weld precision is largely dependent on the welder's skill.

Low-cost, large-scale fabrication industries like shipbuilding and construction, where laser accuracy is not crucial, are still dominated by traditional methods.

2. Speed: Who Wins the Race?

(1)Laser Welding: Lightning Fast

Laser welding machines are the most productive. Compared to conventional arc welding, a high-electricity fiber laser welding system can complete tasks up to ten times faster. For instance, robots equipped with commercial laser welding equipment can weld a car door seam in a matter of seconds, significantly cutting down on production time. According to statistics from the worldwide laser marketplace 2025 forecast, producers adopting fiber laser system have advanced universal performance with the aid of using 30–50%. The capacity to weld constantly with out converting filler substances or electrodes offers laser welding an plain benefit in automation-pushed industries.

(2)Traditional Welding: Slower however Reliable

Traditional welding`s velocity is constrained with the aid of using guide operations and common interruptions, consisting of changing electrodes or adjusting current. On average, an skilled welder can obtain speeds of 10–20 cm/min, while a laser welding machine can attain two hundred cm/min or better beneathneath the identical conditions. In mass-manufacturing environments, even some seconds in line with weld translate to tremendous price and time differences, making fiber laser era the go-to preference for high-quantity manufacturing.

3. Strength: Which Method Delivers More Durable Joints?

(1) Superior Strength of Laser Welding

Laser welds are acknowledged for his or her deep penetration and minimum defects. The weld depth-to-width ratio can attain 5:1 or more, making sure strong bonding. Studies through commercial laser producers in China display that fiber laser welds can reap as much as 95–100% of the bottom metallic energy. This is why industries like aerospace, automotive, and protection depend closely on high-precision laser welders. The constant beam high-satisfactory of a fiber laser slicing and welding device ensures dependable overall performance even below severe conditions.

(2) Limitations of Traditional Welding

In conventional arc welding, big heat-affected zones can weaken the encompassing metallic, ensuing in microcracks and decreased toughness. For example, in shipbuilding or heavy metallic structures, thermal distortion can have an effect on long-time period durability. Moreover, guide welding inconsistencies might also additionally cause defects along with porosity or slag inclusion, decreasing universal joint integrity. Thus, whilst conventional welding stays appropriate for low-value applications, it struggles to healthy the precision and mechanical energy of laser welding systems.

4. Precision: The Key to Modern Manufacturing

(1)Laser Welding: The Epitome of Accuracy

Laser welding represents a brand new preferred in precision engineering. Using fiber laser reassets and automatic movement control, it may obtain positional accuracy of ±0.01 mm. In sectors like microelectronics and clinical tool manufacturing, such precision is indispensable. For instance, at some point of telephone battery tab welding, laser welding machines produce smooth and uniform seams with out unfavorable adjoining microcircuits — some thing conventional strategies can't obtain. The excessive precision laser engraver and UV laser engraving device technology frequently supplement laser welders, forming a whole atmosphere for high-quality metallic processing.

(2)Traditional Welding: Dependent on Human Skill

Manual welding accuracy varies with operator experience. Even the nice welders face problems preserving millimeter-stage precision at some point of lengthy manufacturing cycles. Thermal growth and choppy filler distribution frequently bring about dimensional inconsistencies, requiring post-processing or rework — in addition growing costs.

5. Applications and Industry Use Cases

(1)Laser Welding Applications

The laser welding device has grow to be the cornerstone of business laser manufacturing. Automotive Industry: Used for vehicle doors, roof seams, and exhaust structures in which precision and aesthetics matter. Aerospace: Ideal for titanium and aluminum alloys, lowering weight at the same time as keeping strength. Electronics: Enables best welding of battery cells, sensors, and circuit boards. Jewelry & Medical Devices: Offers non-touch micro-welding that keeps the integrity of sensitive substances. Manufacturers regularly integrate laser marking machines, laser reducing machines, and laser cleansing machines in a unmarried manufacturing line for entire automation.

(2)Traditional Welding Applications

Traditional welding nonetheless prospers in heavy industry, construction, and shipbuilding, in which thick substances and occasional manufacturing prices are priorities. The simplicity of operation and occasional funding make it appropriate for small workshops or restore services. However, as automation expands, even small organisations are turning to transportable laser welding machines and hand held laser welders to beautify flexibility.

6. Cost Comparison and ROI

(1)Equipment and Operation Costs

The preliminary funding in laser welding device is higher — commonly between $10,000 to $60,000 relying on strength and configuration. In contrast, conventional welding structures might cost a little under $5,000. However, long-time period financial savings desire laser structures. For example, a 1000W fiber laser welding system consumes most effective 1–2 kWh in keeping with hour, in comparison to 15–20 kWh for a traditional spot welder. Moreover, laser welding calls for no electrodes, filler wires, or protecting gases, putting off maximum consumable fees.

(2)Maintenance and Labor Savings

Laser welding machines are almost renovation-free, requiring most effective lens cleansing and cooling device checks. On the opposite hand, conventional welding needs common alternative of consumables and professional labor, growing each renovation and human fees. A laser system provider in China reviews that switching to fiber laser structures can lessen manufacturing fees with the aid of using as much as 40% annually.

7. The Future of Welding: Smart, Green, and Connected

The destiny belongs to intelligent, green laser welding technology. As business laser producers in China and overseas combine AI, robotics, and IoT into manufacturing lines, welding precision and performance will retain to rise. The new era of three in 1 laser welding cleansing reducing structures allows customers to weld, clean, and reduce metallic with a unmarried hand-held device — ideal for small organizations looking for custom designed laser solutions. Moreover, as environmental guidelines tighten, the clean, fume-loose manner of laser welding machines aligns flawlessly with worldwide sustainability goals. According to worldwide laser marketplace 2025 projections, the call for for fiber laser system will develop with the aid of using over 20% annually, making it one of the fastest-developing sectors in business automation.

8. Conclusion: The Smart Choice for Modern Manufacturing

When evaluating laser welding vs conventional welding, the benefits of laser era are undeniable. It offers:

①Speed: Up to 10x quicker welding efficiency.

②Strength: Weld joints as robust because the base material.

③Precision: Micron-stage accuracy and minimum deformation.

For industries aiming to beautify productivity, make certain quality, and embody shrewd automation, laser welding machines constitute the destiny. While conventional welding keeps its relevance in cost-touchy applications, the destiny of superior manufacturing — from aerospace to automotive — belongs to laser-primarily based totally answers. Partnering with a relied on laser device manufacturing unit or laser gadget distributor guarantees get admission to to dependable fiber laser welding, laser cutting, and staining answers tailor-made for your manufacturing needs.